Iso 2768 Hole Tolerance H7

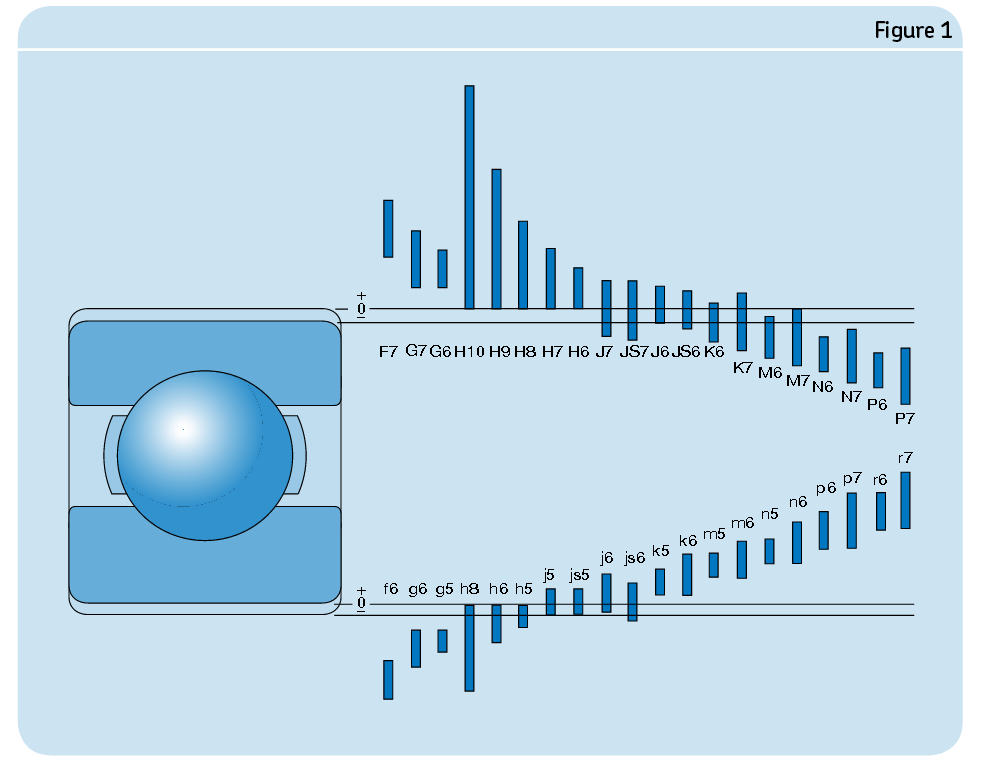

Light Converse Keygen Torrent. ISO Tolerances for Holes (ISO 286-2) ISO Tolerances for Holes (ISO 286-2) Nominal hole sizes (mm). H7 +12 0 +15 0 +18 0 +21 0 +25 0 +30 0 +35. The following defines the preferred tolerance basis for hole and shaft per. Preferred Mechanical Tolerances Metric ISO 286. ISO Tolerance zone calculator Usage The calculator application page is divided into 3 windows. Telecharger Wii Iso Bca Editor V1.00. Calculator window Basic size calculations and results. For example: H7 (hole, tapped hole, or nut) and h7 (shaft or bolt). H7/h6 is a very common standard tolerance which gives a tight fit. The tolerances work in such a way that for a hole H7 means that the hole should be made slightly larger than the base dimension (in this case for an ISO fit 10+0.015−0, meaning that it may be up to 0.015. Coda 2 0 9 Keygen Idm.

Example for the DIN ISO 2768-2 tolerance table. This is just one example for linear tolerances for a 100mm value. This is just one of the 8 defined ranges (30-120 mm).

Engineering tolerance is the permissible limit or limits of variation in: • a physical; • a measured value or of a material, object, system, or service; • other measured values (such as temperature, humidity, etc.); • in and, a physical or space (tolerance), as in a (lorry), or under a as well as a train in a (see and ); • in the between a and a or a hole, etc. Dimensions, properties, or conditions may have some variation without significantly affecting functioning of systems, machines, structures, etc. A variation beyond the tolerance (for example, a temperature that is too hot or too cold) is said to be noncompliant, rejected, or exceeding the tolerance.

Contents • • • • • • • • • • • Considerations when setting tolerances [ ] A primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a process. This can be by the use of scientific principles, engineering knowledge, and professional experience. Experimental investigation is very useful to investigate the effects of tolerances:, formal engineering evaluations, etc. A good set of engineering tolerances in a, by itself, does not imply that compliance with those tolerances will be achieved. Actual production of any product (or operation of any system) involves some inherent variation of input and output. Measurement error and statistical uncertainty are also present in all measurements. With a, the tails of measured values may extend well beyond plus and minus three standard deviations from the process average.